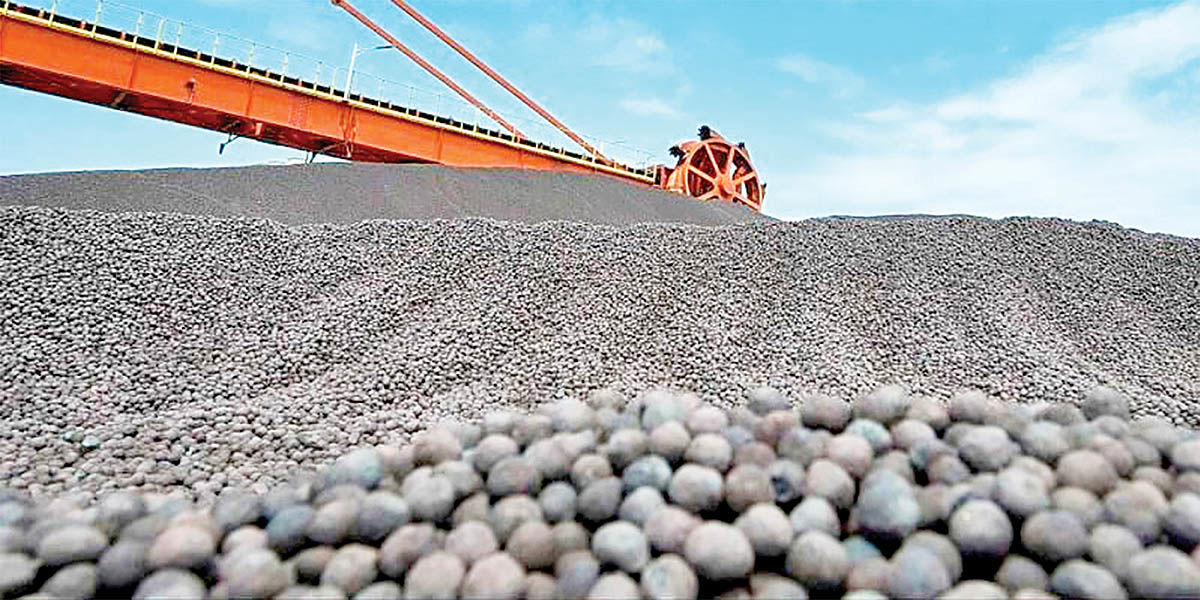

Iron ore pellets

The production of raw iron and steel requires the use of iron pellets (iron re pellets), which are small pellets that are made from iron ore concentrates and certain additives Iron pellets tend to be between 6-16 mm in size. About 63-70 percent of the pellets are iron concentrate, and the essential additives for making pellets make up the remaining 30 percent. These additives usually include lime, lime milk, dolomite, olivine and bentonite.

Iron pellets are used as a raw material for producing raw iron because of the following advantages over fine-grained iron ore:

- The iron pellet has a uniform shape and size, which improves the performance of the high furnace.

- Iron pellet has a higher porosity than fine-grained iron ore, which increases it’s contact with regenerative gas.

- Iron pellet has fewer impurities than fine-grained iron ore, which improves the quality of raw iron produced.

The stages of iron pellet production are:

1- Crushing iron ore: The iron ore extracted from the mines is first crushed into smaller pieces.

2- drying: Crushed pieces of iron ore in dryer, dry.

3- Additives: Additives for dried parts of iron ore are added.

4- Forming: Parts mixed with additives are removed in the form of small pellets.

5- Baking: The pellets formed are cooked in special furnaces.

Iron pellet is one of the important products of the steel industry and plays an important role in the production of raw iron and steel.