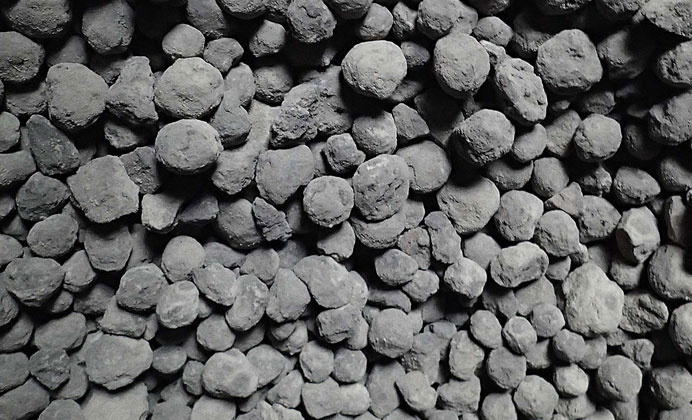

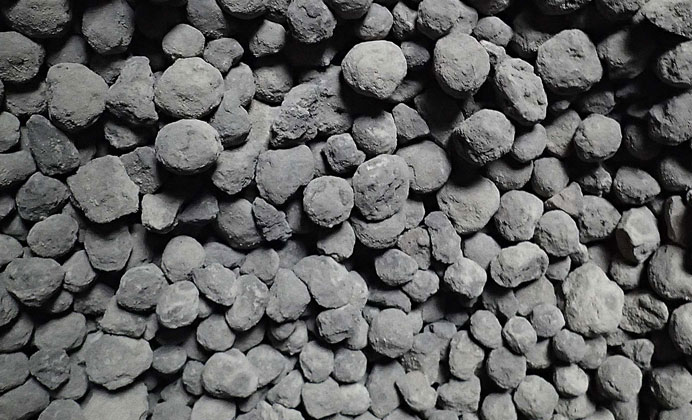

(Clinker)

The main raw material used in the production of cement.

Clinker, which is sometimes referred to as kiln slag, is composed of dark gray grains that have a diameter ranging from 3 to 25 mm. Limestone and aluminum silicate (clay) are heated in rotary kilns at a very high temperature (1400 to 1500 degrees Celsius) to create this substance.

Clinker chemical compounds:

*Tricalcium silicate (allite): about 65%

* Dicalcium silicate (blite): about 15 percent

* Tricalcium Aluminate: About 7 percent

* Tetrachlorium aluminophritis: About 8 percent

* Najizi Ixidhai Meezim, Siddim, Petasim and Ahn

The difference between clinker and cement:

The grains of clinker are hard and solid, while cement powder is soft and easily soluble in water.

The production of cement requires clinker and other additives (such as gypsum) to be mixed together.

Clinker will harden when exposed to air and moisture and lose its adhesive properties, so it needs to be stored in dry conditions away from moisture.

Types of clinker:

Portland clinker: Portland cement is produced using Portland clinker, the most common type.

Aluminate clinker: The production of aluminate cement, which is used for making refractory concrete, is done through the use of aluminate clinker.

Pozzolanic clinker: The production of pozzolanic cement is aided by the use of pozzolanic clinker, which is used to create durable and low-temperature concrete.

White clinker: White cement is made from white clinker and is applied to building facades.

Applications of clinker:

Cement production: Clinker is used primarily to produce different types of cement.

Concrete production: The production of concrete involves the use of cement that is produced with clinker.

Other uses: Clinker is sometimes employed as an aggregate for concrete or as a raw material in the manufacturing of non-medical materials such as ceramics and glass.

Clinker production:

1. Extraction of raw materials: The extraction of limestone and clay from mines is done.

2. Preparation of raw materials: The process of preparing the raw materials involves chopping them into small pieces and grinding them into powder in mills.

3. Formation of slurry: A slurry is formed by mixing limestone powder and clay with water.

4. Preheating: Preheating furnaces are used to heat the slurry to a temperature of approximately 800 degrees Celsius.

5. Clinkering: The heated slurry is then melted by heating it in rotary kilns at a temperature of 1400 to 1500 degrees Celsius. The reaction of raw materials with each other results in the formation of clinker mineral phases at this temperature.

6. Cooling: Quickly cooled molten clinker is taken out of the furnace for cooling. The sudden cooling transforms clinker into hard and solid grains.

7. Grinding: Special mills grind granulated clinker into a soft powder.